Choosing An Electrical Component Cleaner | Ideal Characteristics

Electrical Component Cleaner: Ideal Characteristics

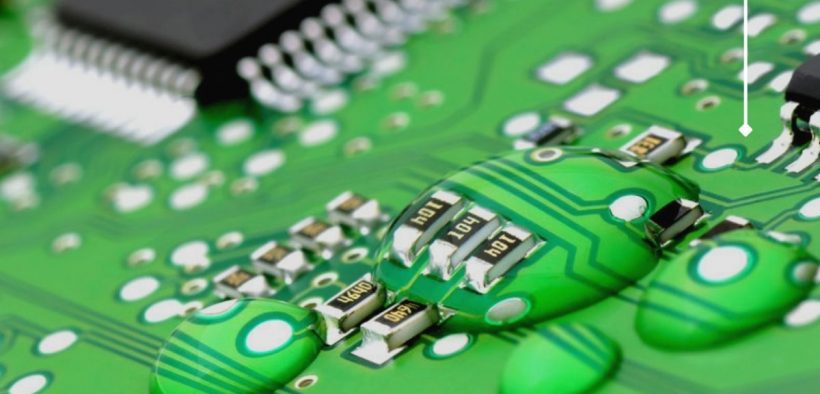

Cleaning is one of the important processes within electronics manufacturing and it has been followed for many years to remove potentially harmful contaminants from electrical components. We all know the importance of selecting the right lubricant and component cleaner in order to protect your machinery or components.

Role of Lubrication

The reliability of electrical utility sorts of equipment like connectors, switchgear, and circuit breakers are possible be improved with modern lubrication technology and practices. In recent years, a variety of synthetic lubricants have established with the ability to perform conventional lubricants at high temperatures, resistance ability to grease dry out, and the skill to guard against wear and corrosion which may cause failure of the electric equipment.

Can Contact Cleaner Damage Electronics?

The type of electrical component cleaner you use can undoubtedly impact the integrity of the parts of your component that you clean and the safety of the cleaning operation. That’s why it’s important to develop an inventory of characteristics that you simply ideally need in an electrical component cleaner before you place an order. During this entry, let’s understand the important characteristics that practically every organization should consider while selecting a cleaner for electrical components.

Ideal Characteristics to be considered for choosing Electrical Contact Cleaner

1. Non-Flammable Composition

Using a cleaner that’s non-flammable is one of the ideal choices for cleaning energized equipment, particularly high-voltage equipment like industrial-grade switchgear. It isn’t always necessary but, it’s the safest option if the contact cleaner is nonflammable if the vapors or liquid could be exposed to sparks, open flames, or hot surfaces hazard.

It is always beneficial to use nonflammable formulation because it helps you store the cleaner without creating a fire

2. High Dielectric Strength

The dielectric during a component cleaner may be a substance that interferes with the flow of electricity through the cleaner, which helps prevent the user from being injured by electric shock while applying the cleaner. The solution with high dielectric strength is essential for cleaning energized components. If you want the cleaner to act as an insulator to protect you while you are using it then always look for dielectric strength in the product specifications while selecting a contact cleaner.

3. Non-corrosive property

Metals are often a robust material and a superb conductor of electricity. This is often why electrical components are frequently composed of metal and situated inside a metal housing that helps protect them. While you’ll always choose a cleaner that’s designed for a selected sort of metal, it often makes more sense to pick one that’s non-corrosive to all or any metal, as electrical components are made up of various sorts of alloys.

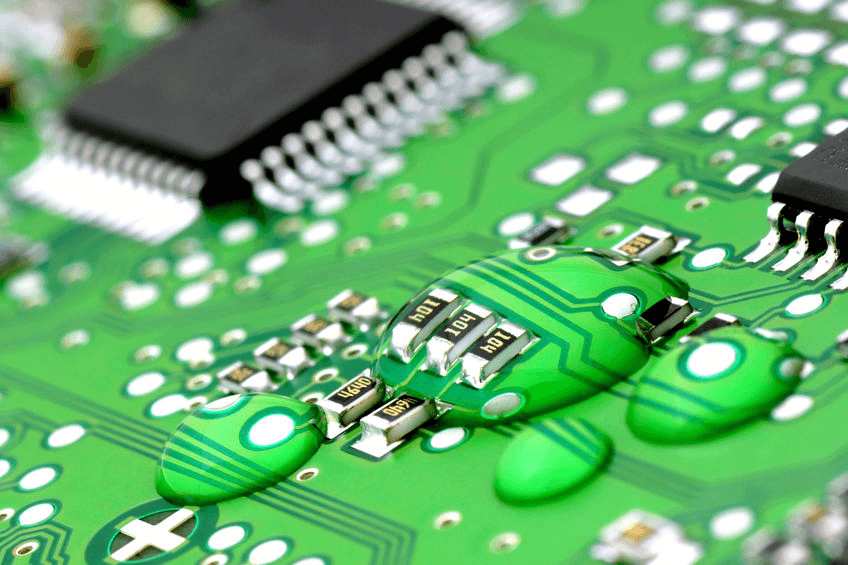

4. Plastic / rubber compatibility

While the contact surfaces of connectors are metal, they’re often housed in plastic, alongside rubber gaskets to seal everything from the surface environment. If the solvent used in a contact cleaner is incompatible with the plastic, then it can create small cracks, or soften the fabric. Rubber seals may swell, shrink or maybe dissolve if exposed to a harsh solvent.

5. Residue-free formulation

Most of the electrical component cleaners we use leave a residue which causes the equipment parts to accumulate dirt and dust particles faster than they would if a non-residue cleaner were used. Non-Residue Formulation is a highly suggested characteristic among electrical component cleaners.

6. High Evaporation Rate

A cleaner that evaporates quickly serves two benefits:

1.It helps you to perform cleaning operations that require a fast turnaround time within the proper time frame.

2.It helps to prevent the cleaner from sabotaging the operation of electrical equipment due to wet components that don’t dry quickly enough.

Where to Buy Electrical Contact Cleaner?

Looking for an Electrical Contact Cleaner? If Yes, MOSIL Lubricants can provide you with the most suitable electronic cleaner solution that features the important characteristics we discussed above.

For your cleaning requirements, you can connect with us at [email protected] or visit our website www.mosil.com for assistance with choosing the best electrical component cleaner.