Bearing failure due to water | Bearing failure analysis

Did you know?

It only needs a small amount of water ( less than 500 ppm ) to substantially shorten the service life of rolling elements in the bearings and eventually cause Bearing Failure. Destructive effects of water on bearings can easily reach or exceed that of particle contamination, depending upon various conditions.

It is not about whether water imparts harm but rather how it does. Knowing these bearing failure causes and damages helps in setting important dryness targets and also helps in bearing failure investigations. Further, when water contamination is unavoidable, understanding these water-induced failure modes can be valuable in the selection of lubricants, bearings, and seals for defensive purposes, etc.

Water: The Scourge of our Machines

No contaminant is more complex than water. The reasons are under study, but it includes the co-existence of water with the oil and its many chemical and physical transformations imparted during service. Moisture-induced problem damages the oil and machines both and certainly lead to operational failure of the bearing.

Water can damage machine surfaces by premature oxidation of the base oil. These oxides combine with more water and a corrosive acidic fluid environment exists.

Oxidation can form sludgy in-solubles and increase oil viscosity. Both the processes impede oil flow and lead to bearing damage. Water and the oxidative environment can amplify the lubrication problems even further.

Failure Modalities- Bearing failure causes

In order to keep these failures to a manageable length and scope, the modalities described here are brief and to the point. Even there are some failures mentioned, that are largely derived from conjecture but are believable.

Hydrogen-induced fractures

Also known as blistering or embrittlement, here, the source of hydrogen can be water, but also electrolysis and corrosion.

Water is attracted to microscopic fatigue cracks in balls and roller by capillary actions. Once in contact with the free metal ions, water breaks down and releases hydrogen. This causes crack propagation and fracture.

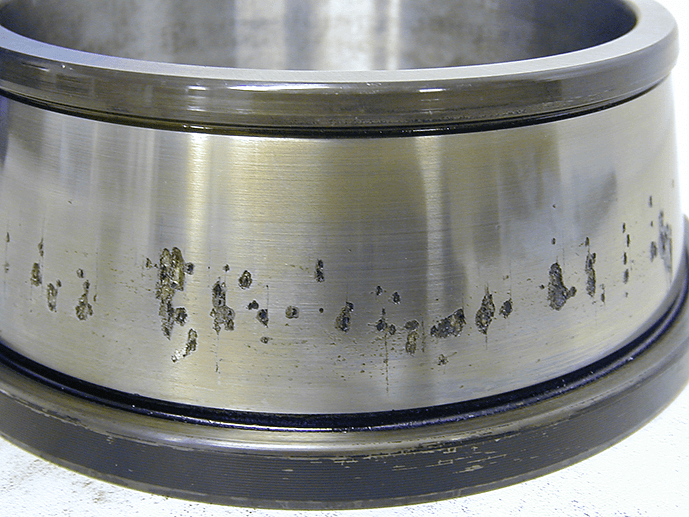

Corrosion

Rust requires water. Soluble water contributes to rust formation. Water gives acids their corrosive potential. Pitted surfaces on bearing raceways and rolling elements disrupt the formation of critical elastohydrodynamic oil films that give film strength to control fatigue and wear. Fretting is also accelerated by free water.

Oxidation

Many bearings have a limited volume of lubricant. High temperatures bounded by metal particles and water consume the anti-oxidants and rid the lubricant from the needed oxidative protective environment. The negative consequences of oil oxidation include sludge, varnish and impaired oil flow.

Additive depletion

We learned that water aids in the depletion of anti-oxidants, but it also cripples the performance of a host of other additives, viz; AW, EP, rust inhibitors, detergents, dispersants. Water can hydrolyze some additives, agglomerate others or simply wash them out of the working fluid. Sulphur-phosphorous EP additives can transform into sulfuric acid, thus increasing the acid number.

Oil flow restrictions

Water is highly polar, and as such has the interesting ability to mop up oil impurities that are also polar to form sludge and emulsions. These amorphous suspensions (oxides, dead additives, particles, carbon fines, and resins) can enter critical oil ways, glands, and orifices that feed the bearings.

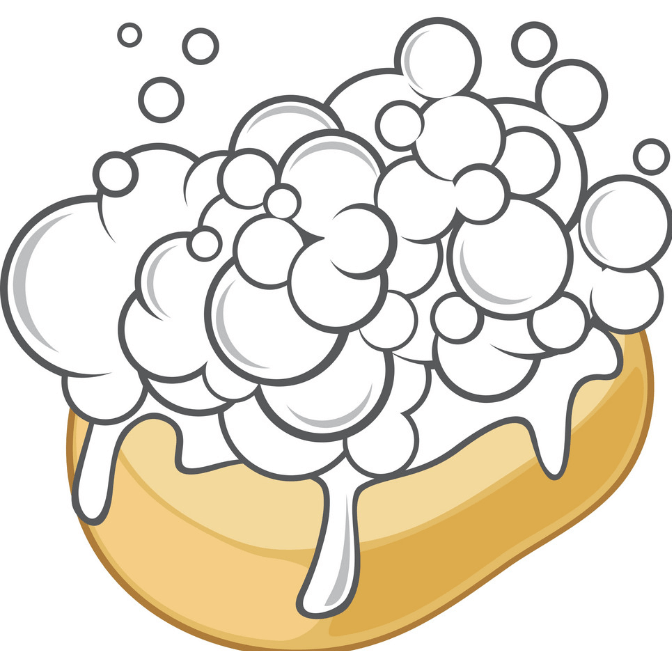

Aeration & Foam

Water lowers an oil’s interfacial tension, which can cripple its air handling ability, leading to aeration and foam. It takes about 1000 ppm water to turn a bearing sump into a bubble bath. Air weakens the oil films, increases heat, induces oxidation, and can cause interference with oil flow; all catastrophic to the bearing. Aeration and foam can also disable the effectiveness of oil slingers, ring oilers, and collar oilers.

Microbial contamination

Water is a known promoter of micro-organisms such as fungi and bacteria. Over time, these can form thick biomass suspensions that can plug filters and interfere with oil flow, Hence microbial contamination is also corrosive.

Water washing

When bearing grease is contaminated with water, it softens the lubricating grease and flows out of the bearing. Water spray can also wash the grease directly from the bearing, depending on the grease thickener and conditions.

Inference- How to Prevent Bearing failure

The solution to the water problem is the proactive solution, i.e; preventing the intrusion of water into the bearing lubricant and bearing environment. The only water that doesn’t cause harm is the water that doesn’t invade the system.

Contamination exclusion tactics are always a wise maintenance investment. The cost of removing water from the lubricant exceeds any investment made to exclude it from its entry, so never skip when it comes to proactive contamination control.

To know our specialty lubricants for industrial bearings, you can visit our bearing lubricants product page here- Bearing Lubricants (General Purpose)