Previous Article

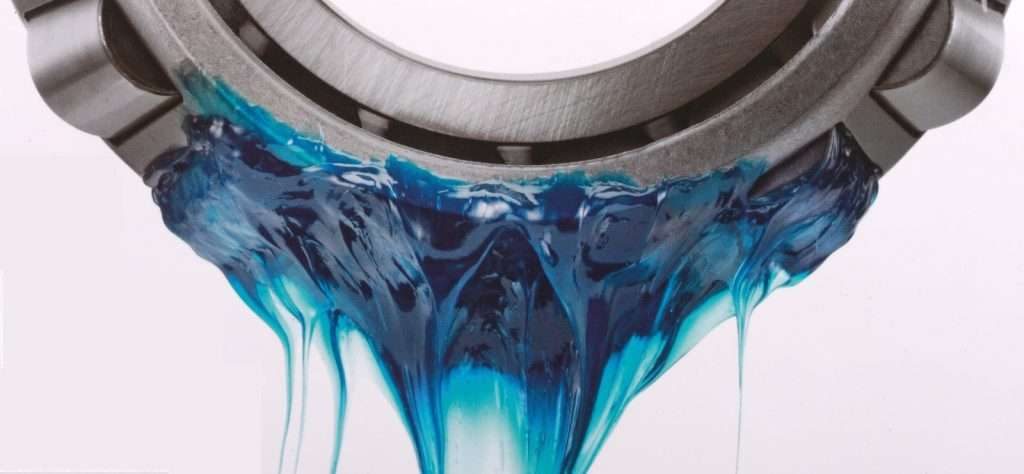

Tips on Picking out Industrial Lubricants

Next Article

Guidelines for Corrosion Prevention

Next Up

Guidelines for Corrosion Prevention

November 14, 2018